UKAS Accredited Calibration Services – ISO 17025

Young Calibration successfully transitioned to ISO/IEC 17025:2017 after its recent UKAS assessment. The company continues to offer world leading UKAS accredited calibration services for gas flow, fluid flow, air velocity and pressure instruments. United Kingdom Accreditation Service (UKAS) is a member of the International Laboratory Accreditation Cooperation (ILAC) which provides mutual recognition to overseas accreditation bodies, governments and industries, such as NIST, DakkS, COFRAC, DANAK, ENAC, Accredia and IPAC.

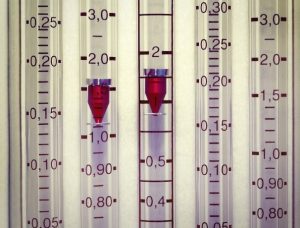

UKAS Airflow Calibration for all meter types including the popular VA or variable area flowmeters and mass flow controllers and flowmeters (MFC / MFM). The UKAS accredited laboratory covers an extended flow range from 1 cc/min to 1250 l/sec, enabling the calibration of small leak testing machines to 300 mm diameter laminar flowmeters. All accredited flow calibrations are undertaken on dry air with options for inert gases on a non-accredited but traceable basis. More recently the laboratory has dedicated a second accredited flow calibration rig for the calibration or air sampling flowmeters utilised in the asbestos and environmental sectors.

UKAS Water Flow Calibration for magnetic, coriolis, turbine, variable area, wedge and ultrasonic style meters from an ultra-low flow rate of 1 ml/hour for nano-flowmeters and infusion analysers to 1000 l/min for industry standard flow meters. Ultra-low flow calibrations can be offered with a measurement uncertainty of 0.1% on pure water whilst meters from DN3 to DN80 can be offered with a 0.15% measurement uncertainty. All meter connection types whether threaded, flanged and clamped can be accommodated in the test rigs with the necessary upstream and downstream flow conditioning lengths. Further enhancements to the facility will see the upper range increase to 4000 l/min to cover meters sizes to 150 mm.

UKAS Oil Flow Calibration covering 0.5 to 440 l/min on ISO grade mineral oil with a viscosity range covering 5 – 20 cSt for the calibration of turbines, positive displacement, gear, helical, coriolis and sprung VA style flowmeters. Further non-accredited calibrations can be completed on ISO 4113, alcohols, JET-A1, bespoke aviation oils and dielectric fluids.

UKAS Air Velocity Calibration for thermal, vane, rotating cup, pitot tube, isokinetic probes, CTA’s yaw probes and ultrasonic meters covering a complete range of 0.05 to 80 m/s. The two accredited wind tunnels allow for full air velocity profiling using 1D and 2D laser doppler anemometers and the determination and characterisation for blockage correction studies. The low velocity range of 0.05 m/s allows for accurate calibration of omni-spherical probes and cleanroom turbulence meters. Air velocity calibrations of emissions isokinetic sampling probes, L pitot tubes, S Pitot tubes and the generation of pitot tube coefficients, gamma or K factors up to an air velocity of 80 m/s. The internal laboratory procedures cover the requirements for emissions sampling to ISO 10780 and ISO 3966 and the requirements of the Source Testing Association (STA). More traditional anemometers such as thermal, vane and omni-spherical probes are calibrated on an open jet wind tunnel with a 1D laser doppler anemometer across an air speed range of 0.05 to 80 m/s depending upon the physical instrument size. Accurate, repeatable air profiles can be generated and measured for turbulence studies and research activities across both the accredited wind tunnels with the UK’s leading measurement uncertainty.

UKAS Oxygen Pressure Calibration is a recent addition to the UKAS schedule as the company continues to grow and offer an extended range of services. Housed in a newly designed ISO Class 6 to ensure gauges and transducers are free from external contaminants, gauges can be UKAS calibrated in an oil free system across 0 – 400 barg. Within the cleanroom facility, dedicated hardware exists for the complete oxygen cleaning and assessments to ASTM G93 standard covering all the requirements for flushing, sampling, gravimetric analysis, microscopic analysis, black/white light assessments and for complete confidence in cleanliness full molecular FTIR analysis is available to detect any hydrocarbon residues. The oxygen cleanroom offers high performance cleaning and calibration for GOX/LOX instruments utilised in submarine, aviation and medical sectors that require complete confidence of a particle and oil free system.

UKAS On-site Calibration covering the whole of the UK and EU is available for pressure, electrical and temperature simulation. Our experienced Calibration Engineers can undertake calibration duties for production lines, R&D Centres, manufacturing, service centres, medic centres and test houses. Engineers are available to travel on short notice and work out of hours to minimise your process disruptions. An extended range of non-accredited calibration services are available for gas flow calibration, liquid flow calibration, humidity, mass, torque and temperature.

Contact Details

5 Cecil Pashley Way

Shoreham by Sea

West Sussex

BN43 5FF

United Kingdom

Tel: +44 (0)1273 455572

Email: ay@youngcalibration.co.uk

Web: www.youngcalibration.co.uk