A world leader in bespoke roll-formed metal sections.

Welser Profile is a world leading developer and manufacturer of bespoke metal roll-formings, often called metal sections or metal profiles. From process tracking and rails, conveyor components, solar panel mounts, automotive & commercial vehicle chassis components, to off-highway cabs for ROPS/FOPS protection, Welser manufacturers complex, high accuracy metal roll-formings for all markets.

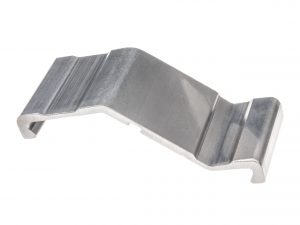

What is a Welser roll-forming?

Although the cold roll-forming process itself is actually nothing like the extrusion process, the end result is rather like an extrusion, but more accurate. Also, the part can be made from stronger metals than aluminium or magnesium, and with the added benefit of being able to add features like slots, embosses, clips and even captive nuts along the length of the part, all achieved within a single roll-forming process.

The Welser roll-forming process combines high volume with tight tolerances, which means you can cost-effectively create thousands of metres of a very accurate cross-section in materials like high strength steels, stainless steels, and various non-ferrous metals, with features along the part length, making it ready to plug directly into your production process. You cannot do this with an extrusion.

For those components where further shaping is required, Welser can also bend the part and shape each end of the part.

Metal thickness from 0.3mm up to 8.2mm can be formed, and this is done at room temperature, so metal properties are maintained. Cross-sections can be welded closed as part of the single roll-forming process (stainless steel profiles can be laser welded) to create an air-tight or oil-tight shape, and different profiles can then be welded together, to create even more complex structures.

For more roll-forming process details, please click here.

What can Welser Profile do for you?

Due to the vast array of options possible, Welser very much encourages our customers to work with us from the early stages of component development. Your expertise and bespoke requirements can then be combined with our roll-forming knowledge, and many years of experience has shown us that this leads to the most cost-efficient and effective metal sections. Our customers are regularly amazed at what is possible, at how working together to optimize a design can lead to shapes not previously considered, at how several functions can be combined and at how aesthetic improvements can all be brought together for a huge leap forward for their own product.

In short, you benefit from having the optimum metal section for your specific requirement, which saves you time and money in your production process.

For inspiration, have a look at some of the applications & markets we have been involved with here.

Who are we?

Welser Profile is over 350 years old and is still led by a member of the Welser family. We pride ourselves in maintaining long-term relationships with our customers over many decades.

We manufacture in Austria, Germany and the USA. We have sales offices all over the world, allowing us to be close to our customers, wherever they are.

We manufacture our own roll-form tooling, our own press-tooling, and we modify our roll-forming machines to our own specifications. This enables an incredible depth of quality control. Welser is certified to ISO 9001, ISO 18001, ISO 14001, ISO 50001, ISO TS16949 & ISO 45001 and we are always working to improve our quality.

We are the world’s most technically advanced metal roll-forming company, and we specialize in delighting our customers with solutions that advance their products.

If you would like to know more, please do not hesitate to contact me:

Nick Jeal

UK & Ireland Area Sales Manager

Tel: 0161 491 5210

Email: n.jeal@welser.com