Körber Pharma Packaging

Körber is an international technology group with around 10,000 employees and more than 100 locations worldwide.

We turn entrepreneurial thinking into customer success and shape the technological change. In the Business Areas Digital, Pharma, Supply Chain, Tissue and Tobacco, we offer products, solutions and services that inspire.

At the Körber Business Area Pharma we are delivering the difference along the pharma value chain with our unique portfolio of integrated solutions.

Product and service offerings

Swiss-based Körber Pharma Packaging is a specialist developer and producer of highly integrated, modular and automated solutions and systems for pharmaceutical secondary packaging. Dividella Solutions describe a highly distinctive modular and integrated approach to secondary packaging for the pharmaceutical industry based on specific expertise in integrated and monomaterial solutions and of the packaging requirements for parenteral products and forms a key part of the integrated offer by pharmaceutical and biotech experts Körber Group and its Business Area Pharma.

Over more than 40 years, Körber Pharma Packaging has established a proven record of accomplishment in highly innovative and effective solutions for secure and flexible handling and packaging of pharmaceutical products. Based in Grabs in the Canton of St. Gallen in eastern Switzerland, the company counts 20 of the world’s largest pharmaceutical companies among its clients, including the top ten.

Patented Dividella NeoTOP top-loading and NeoTRAY feeding systems form the basis for solutions that have continually evolved to provide the most up-to-date, patient-friendly and environmentally responsible solutions and form the basis for complete secondary packaging solutions for medicinal parenteral products that can be difficult to stack, such as needles, injector pens, vials and syringes.

Körber Pharma Packaging top-loading and side-loading solutions, along with patented feeding systems, enable product handling with extreme care and safety while maintaining high output.

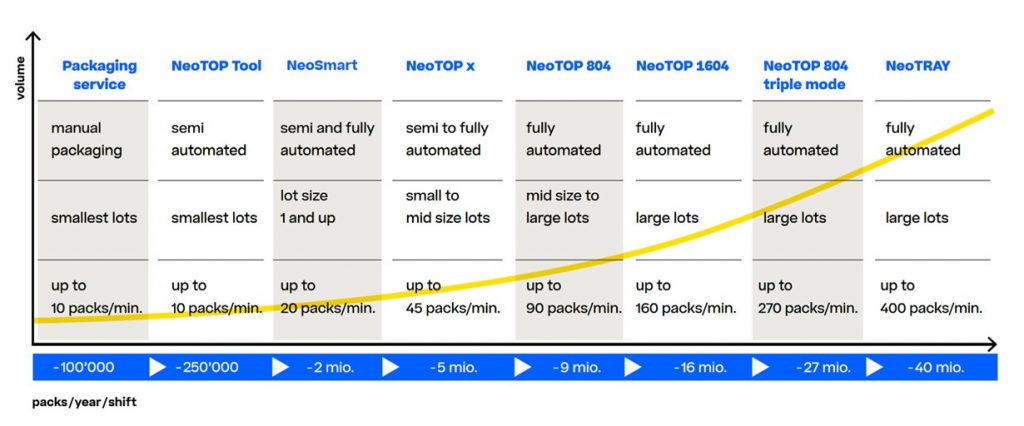

Körber Pharma Packaging implements a customer-orientated service, focusing on identifying the optimal packaging solution for any client, with the ideal solution chosen according to production volume, batch size and packaging requirements. All top-loading styles of packaging can be produced on Körber Pharma Packaging flexible and adaptable Dividella NeoTOP packaging systems, whether for clinical trials or establishing a market presence or full product launches; when packaging high volumes of low count packs the Dividella NeoTRAY concept is the best fit.

The packaging systems are designed with high attention to detail and precision, with each machine optimised for various load sizes. The Dividella NeoTOP x handles small to medium-sized lots, whereas the Dividella NeoTOP 804 and 1604 are designed for medium to large-sized lots and the NeoTRAY for high output and large lots.

Customers also benefit from Körber Pharma Packaging’s extensive engineering support, working in partnership with clients to identify and develop optimized solutions for the safe packaging of sensitive products. Körber Pharma Packaging’s process is guided by the supreme goal of minimizing total cost of ownership (TCO) and total cost of package (TCP) through the use of monomaterials, optimized pack sizes for cold chain and simplicity for the end user.

The modularity of Körber Pharma Packaging’s solutions extends past machine design to packaging formats and integration with other offerings from Körber Business Area Pharma, delivering enhanced functionality, flexibility and reduced overall costs. An almost unlimited number of packaging formats can be accommodated, with high emphasis on monomaterial solutions that deliver powerful bottom line and sustainability benefits.

Flexible feeding systems for parenterals

Dividella presents a variety of feeding technologies for parenterals. Its wide and flexible range are scalable and customised to assist the packaging of up to 500 objects per feeding unit. Products can be aligned, spread, and individually checked before insertion and linking to upstream machines.

TOPLoading solutions by Dividella for the packaging of pharmaceutical products are characterized by:

- Flat blanks for carton and partition – printable on all sides

- Safe automated erecting of pack

- Safe loading process (100% verification after loading)

This offers a variety of advantages for pharma companies and their customers, influencing the complete production and logistical process and having a positive effect on Total Cost of Ownership (TCO) and Total Cost of Package (TCP).

Use of Parenteral Packaging and the latest trends

Users of Dividella’s equipment return time and time again to adapt their existing system or to acquire new lines. The company manufactures quality, easily modifiable, easy-to-use and excellently serviced equipment, which is tailored to the individual needs of the client.

NeoTOP Packaging Solutions

An almost unlimited number of packaging can be processed, whether the pharmaceutical product to be packaged is inclusive of a blister, de-nester, thermoformer, or magazine.

Dividella AG

Werdenstrasse 76, CH-9472 Grabs

Office: +41 (0) 81 750 3387

m.berger@dividella.ch

www.dividella.com