Precision Polymer Engineering Ltd

Precision Polymer Engineering is a leading manufacturer of high-performance elastomer seals and gaskets. With over 40 years’ experience, PPE provides products and services to solve critical sealing problems, by supplying sealing solutions that perform in difficult applications, across a wide range of industries, including:

- Food, dairy & beverage processing

- Pharmaceutical & biomedical processing

- Chemical processing

- Oil & gas extraction and processing

- Semiconductor processing

Our specialist sealing engineers are on hand to help you improve efficiency and reduce costs in your operations. By advising on the optimal sealing material for the exacting demands of any processing application, PPE can affect substantial positive change on many areas of operation. These include:

- Better reliability

- Increased service life

- Extended planned maintenance cycles

- Improved operating margins

- Lower cost of ownership

INNOVATIVE MATERIALS

PPE offers sealing components in nearly every material family – including FKM, FEPM, FFKM, EPDM, NBR, HNBR and silicone. Many of PPE’s material grades meet various international approvals and conformance requirements such as FDA (food), 3A 18-03 (dairy) and USP Class VI (pharmaceutical).

Combining innovative material science with engineering expertise in customising the optimal seal design, PPE can deliver exceptional sealing solutions for pumps, valves, mechanical seals, pipe couplings and reactors in any processing application.

Perlast® perfluoroelastomers (FFKM) provide the highest level of thermal and chemical resistance available, making them ideal for use in the most demanding sealing applications. By using PPE’s Perlast® seals, many manufacturers of process equipment have been able to extend the operating capability of their original equipment without expensive valve and pump redesigns.

Detectaseal® is PPE’s a range of metal detectable and X-ray detectable elastomer compounds, which have been designed specifically to meet the stringent demands of the pharmaceutical and food processing industries. The range includes EPDM, Nitrile, Silicone and Fluorocarbon (FKM) materials and offers the latest advance in contamination detection and containment.

PRODUCT OFFERING

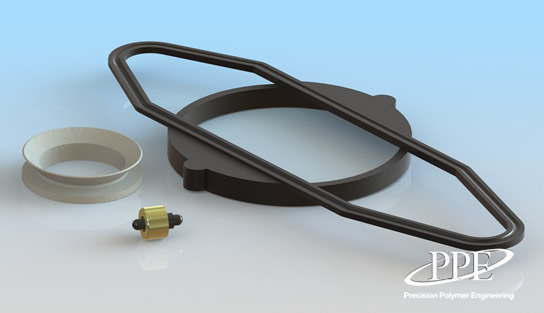

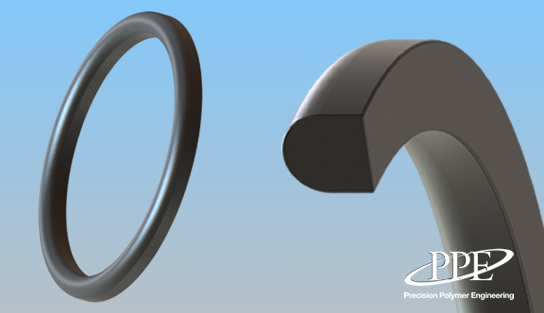

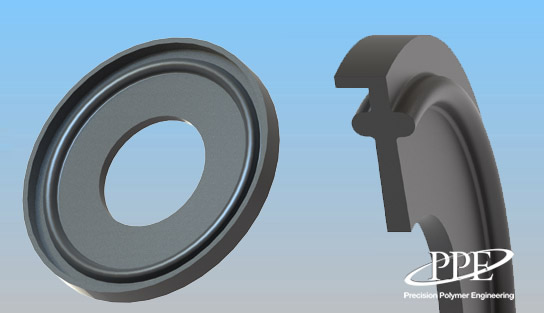

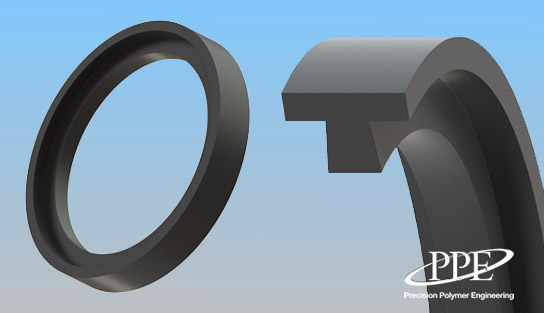

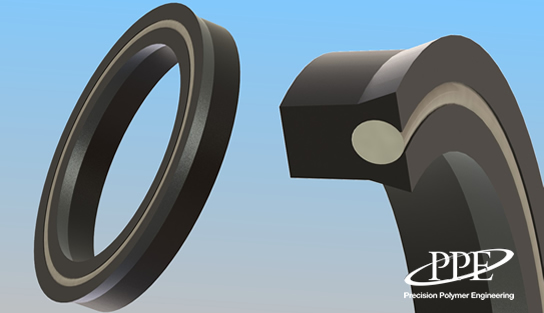

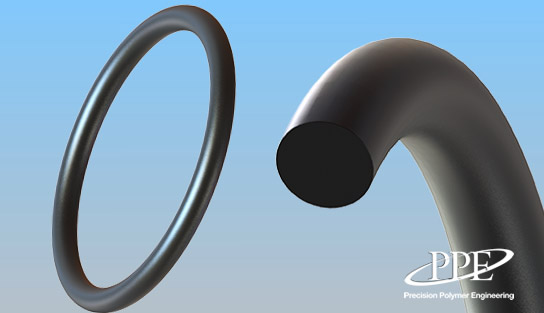

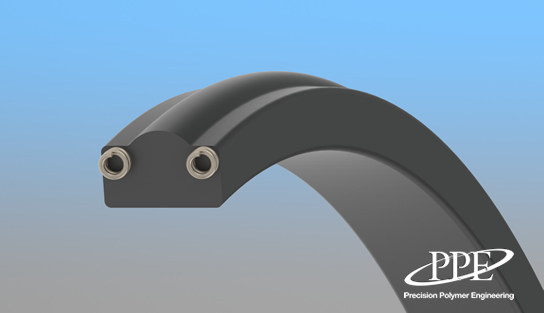

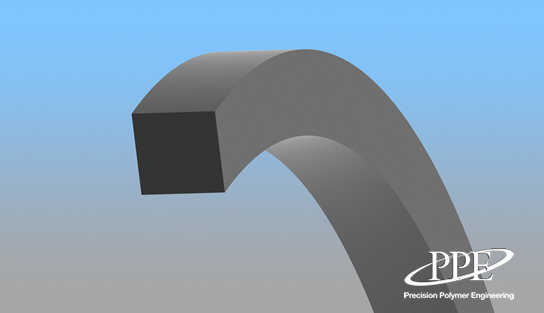

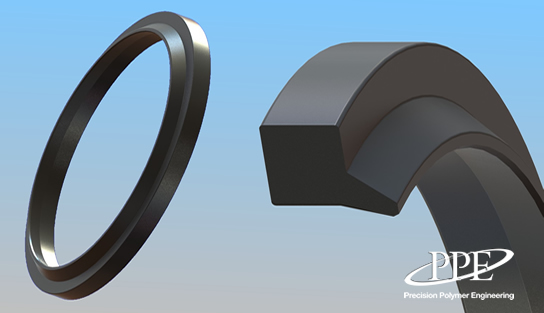

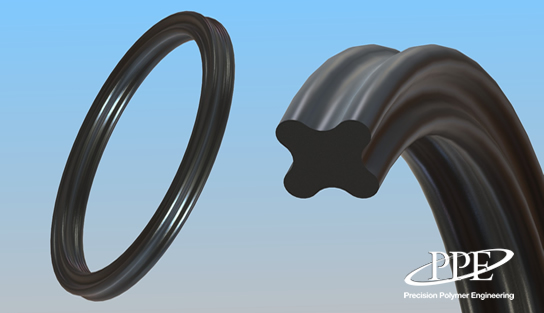

PPE’s elastomer materials can be moulded into infinite geometries, with profiles and sizes to suit any sealing application. From the smallest micro O-ring to more complex composite parts, our objective is to meet the needs of the customer, with a variety of high-performance sealing solutions. Examples of products supplied include:-

- Standard and non-standard sized O-rings

- HyClamp™ sanitary gaskets for pipe couplings

- RJT O-rings

- DIN11864 O-rings

- DIN11851 D-seals

- IDF seals

- SMS 1149 seals

- Diaphragms

- X-rings

- T-seals

- S-seals (spring seals)

- Lip seals

- Wiper seals

- Micro seals

- Custom designed components

SERVICES

With leading polymer scientists and experienced engineers on-hand in the UK and USA, plus an expansive product range, PPE is the ideal partner for critical sealing support.

Component Design – Is your sealing system is optimized for your application? PPE’s custom component design service starts with the original component specification and design through to precision moulding in recommended materials. PPE handles each step accurately and reliably for the highest quality parts every time.

Consultancy – Speak to us to get professional advice and consultancy on any sealing challenge. We can help identify the best performing seal type, profile and material for the demands of any application. Testing capabilities include chemical compatibility, thermo-mechanical evaluation and post-use/failure analysis, conducted in our test laboratories located in the UK and USA.

CONTACT

Precision Polymer Engineering Ltd

Greenbank Road

Blackburn

BB1 3EA

England

Tel: +44 (0)1254 295 400

Email: prepol.sales@idexcorp.com

PPE LLC

3201 S. Blue Bell Road

Brenham

TX 77833

USA

Tel: +1 979 353 7350

Email: prepol.sales-usa@idexcorp.com

Website: www.prepol.com