Hydro International Ltd

Hydro International Ltd is a global company that provides advanced products, services and expertise to help municipal, industrial and construction customers to improve their water management processes, increase operational performance and reduce environmental impact.

With over 30 years of experience and a reputation for engineering excellence, businesses and public organisations all over the world rely on Hydro International products and services to reduce flood risk, improve water treatment and protect the environment from water pollution.

Headquartered in Clevedon, UK, Hydro International has a network of over 80 distribution partners and serves customers in more than 40 countries.

Industrial Process Water Solutions

Meet environmental obligations, improve operational efficiency and cut maintenance costs by managing, recycling and reusing process water and wastewater.

Water scarcity, increasingly stringent effluent discharge regulations and operational efficiency drivers represent real challenges for water-intensive industrial businesses, with process water use, treatment and discharge generating both cost and risk.

We can help businesses to use water more efficiently, recover valuable processing by-products, meet regulations and protect the environment—saving money and reducing financial and legal risks.

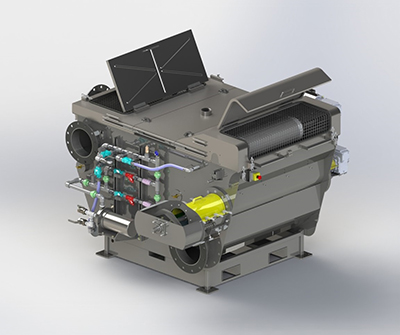

The Hydro MicroScreen™

Drastically reduce the cost, footprint and energy consumption for industrial and municipal wastewater, process water and stormwater treatment.

The Hydro MicroScreen™ is a low-energy, small-footprint rotating belt screen that delivers exceptional solids removal from process water and wastewater. Maintaining efficiency even at peak design flow rates, it enables operators to meet discharge requirements, increase efficiency and save money.

Applications

Hydro MicroScreenTM can help a wide range of industries to improve efficiency and cut pollution:

- Tanning, leather and hide processing

- Pulp and papermaking

- Mining, metals and ore processing

- Bottling and beverage production

- Brewing, distilling and wine making

- Food processing and production

Industrial water treatment increases efficiency at carrot processing facility

Hydro MicroScreen™ removes 100% more solids from process water than existing screening technology.

Situation

A large US carrot processing company wanted to improve its process water treatment at its premier baby carrot processing facility in California in order to reduce the handling cost of carrot pulp and solids and improve its water recycling efficiency

The Problem

Baby carrots are created by cutting carrots into small segments, then peeling, polishing and washing them. This process generates significant quantities of carrot pulp that must be removed from the process water and disposed of.

The facility was using a gravity disc screen with a 185-mesh (81 µm) screen opening to remove these solids from its process water, and it was feeding the effluent to a spray system in order to recycle the process water onto its fields.

Solid content in the spray system reduces the effectiveness of the spray, however; reducing the solids content in the spray system would increase the area that the spray could cover, and increase the system’s efficiency—saving the company money.

In addition, producing drier solids would reduce the weight of pulp, cutting the cost of handling and disposing of this by-product material.

Solution

The company approached Hydro International and requested a pilot test of the Hydro MicroScreen™ rotating belt screen to evaluate the system’s performance for carrot processing applications.

Glenn Murphy of Hydro International’s pilot testing team reviewed the facility’s requirements and recommended the MS28 model with a 158/1000 belt. He designed and set up a test system tailored to the facility’s specific influent flow rate, adjusting the system’s dewatering zone compression in order to generate dry solids output on startup.

He also advised the site owner on optimal operation protocols, recommending solutions to common issues such as loss of system pressure during periods of high demand on the water supply line.

The Hydro MicroScreen™ performed extremely well during testing, achieving an overall total suspended solids (TSS) removal efficiency measured at 90%.

The Hydro MicroScreen™ removed 100% more solids than the existing screening technology for a given volumetric feed.

The more efficient dewatering process also produced a visibly drier solids product, achieving a 30% reduction in pulp solids output.