Fraser Technologies

Fraser Technologies provides expert advice and a wide range of world-leading chemistries and equipment solutions for component cleaning, electronics soldering, and heat transfer and carrier fluids. Working closely with customers to understand their individual challenges, Fraser Technologies can help extend the life of existing processes and equipment; recommend and install new equipment; or help to improve efficiency and significantly reduce environmental impact.

Solvent Cleaning

Fraser Technologies supplies both solvent and aqueous solutions, depending on the cleaning requirements of the customer. For solvent cleaning, the Opteon™ range from Chemours™ is a safe and cost-effective option. While people may be inclined to avoid solvents due to their controversial history, many new generation solvents are extremely safe and environmentally-friendly.

The newest product in the Fraser Technologies portfolio is Opteon™ SF80, a specialty fluid designed to meet the high specifications and demands of the industrial cleaning market. It is a safe, non-flammable, and environmentally friendly solvent with no ozone depletion potential, an ultra-low global warming potential (<2), and does not contain any products regulated under F-gas regulations. SF80 is an effective replacement for nPB, TCE, HCFCs, PFCs, HFCs and HFEs solvents, and is becoming known as the leader within a variety of cleaning applications such as vapour degreasing, oil and grease removal, precision cleaning, high solvency defluxing, and silicone removal, amongst many other uses.

SF80 has the lowest Global Warming Potential (GWP)* and the highest KB (Kauri-butanol) value of any fluorinated solvent on the market by a significant margin. On average, competitors’ new generation products have a GWP of around 40, while SF80 has a GWP of less than 2. The overall impact a change like this can have on a business can be enormous.

This has recently been the case for a prominent aerospace manufacturer customer, who was looking for an alternative to the high-GWP solvent they were using. Previously, the customer was using 7 Metric Tonnes of solvent per year, so Fraser Technologies worked with them to approve SF80 and reduce this. The team assisted in optimising the customer’s processes to reduce solvent consumption and introduced a solvent recovery process to allow them to further reduce waste and reuse the recovered solvent. This has taken the customer’s overall usage of solvent down by 28%.

While the former product was less expensive than SF80, the reduction in solvent usage has shown a cost reduction of around £30,000 per year as well as a significant reduction in CO2 equivalent emissions.

Aqueous Cleaning

As well as solvent cleaning solutions, Fraser Technologies also provides aqueous solutions. Aqueous cleaning is effective across multiple metals including steel, brass, copper and stainless steel, with fast and effective removal of medium to heavy soils including cutting fluids, grease and general particulate. Fraser Technologies supplies the KlensTek® M Series of aqueous metal cleaning agents, which are designed to provide high-level results while maintaining stringent environmental and health and safety standards.

Cleaning Equipment

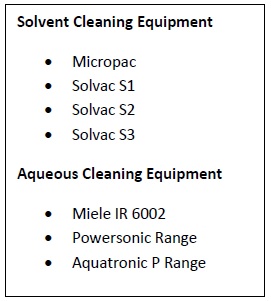

Along with bespoke chemistries, Fraser Technologies also provides the necessary equipment for every cleaning requirement. The solvent cleaning process has three stages – cleaning, rinsing and drying, which are typically carried out beneath a sealed lid, either in a single access or multi-tank system. While these systems have various benefits, such as small shop floor footprints and minimal waste, one of the most significant benefits is the automation they all provide. For the most part, the systems can be started and then left until finished, increasing overall capacity in the manufacturing process.

drying, which are typically carried out beneath a sealed lid, either in a single access or multi-tank system. While these systems have various benefits, such as small shop floor footprints and minimal waste, one of the most significant benefits is the automation they all provide. For the most part, the systems can be started and then left until finished, increasing overall capacity in the manufacturing process.

For aqueous cleaning, Fraser Technologies offers a diverse range of aqueous component cleaning systems to suit a variety of applications. The company evaluates existing processes and requirements to select a solution that delivers suitably fast, effective cleaning cycles using superior technology. The team can also design customised machines if none of the standard options are suitable for the requirements.

Working with Fraser Technologies

A willingness to go above and beyond for customers is part of the Fraser Technologies overall ethos. The highly experienced team provides advice on the best options to suit individual business needs; supplies the exact chemistry and equipment required to produce high-quality results; and gives after-sale support to ensure that the cleaning solution in place continues to meet high standards, and to help with any challenges that may arise.

Over the last 50 years, Fraser Technologies has built its expertise around meeting technological advances, adapting to legislative changes, and solving environmental challenges for companies in the aerospace, defence, electronics, medical, optics and automotive industries. The company offers expert knowledge in a variety of sectors; an independent range of new generation products; comprehensive after-sales service; and a commitment to improving performance, productivity, environmental performance and operator safety. But most importantly, the company becomes an extension of its customers’ teams in order to understand their challenges, and uses its expertise to offer best-in-class solutions.

*Global warming is a gradual increase in the overall temperature of the earth’s atmosphere, generally attributed to the greenhouse effect, caused by increased levels of carbon dioxide, CFCs, and other pollutants. GWP is used to represent the equivalent of Co2 being released into the atmosphere. So 1kg of CO2 = a GWP of 1.

Visit Website – Click Here