Franklin Miller Inc.

For 100 years and three generations, Franklin Miller Inc. has been a leader in size reduction technology involving crushers, shredders, grinders, wastewater treatment systems and more. Our unique combination of experience in both dry solids processing and liquid or pressure seal systems has made us uniquely capable of solving many difficult customer process problems.

Our commitment to leadership starts with our extensive engineering, research and development. Our test lab is available for testing of customer materials. We specialize in matching proven solutions to your specific process problems –from stock and customized machinery to fully integrated systems. We’re cutting problem solids down to size in plant operations worldwide.

Crushers

Franklin Miller offers a wide range of crushers, lump breakers, mills and particle sizers. These products improve bulky powder consistency and flow properties in gravity, pneumatic and vacuum systems. Our products can reduce dry, moist,sticky, wet, friable or tough materials that are often difficult to handle.These units can handle large or small chunks, lumps, slabs, sheets and flakes.

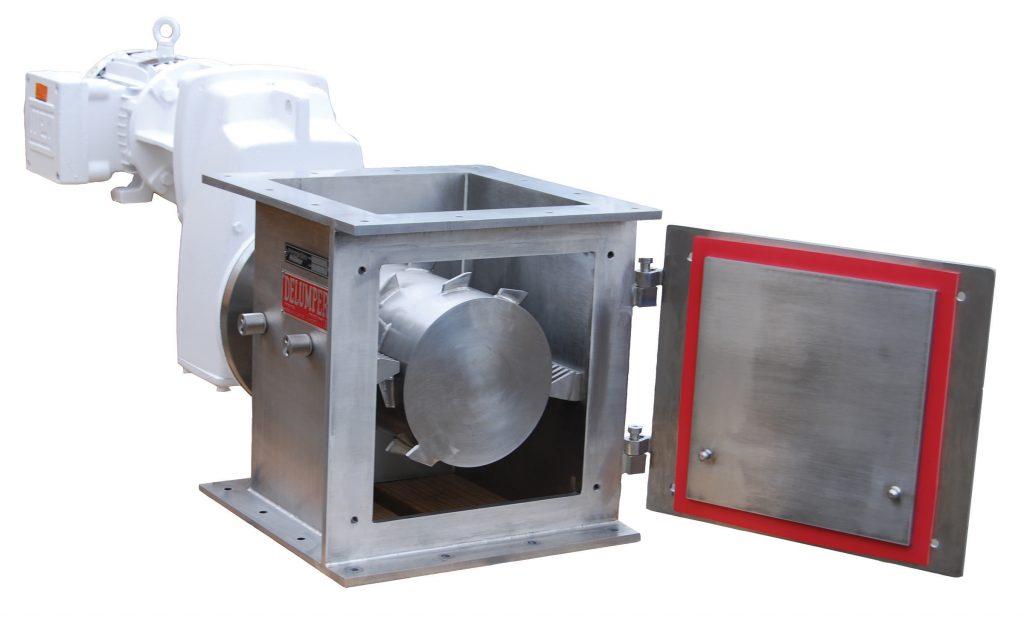

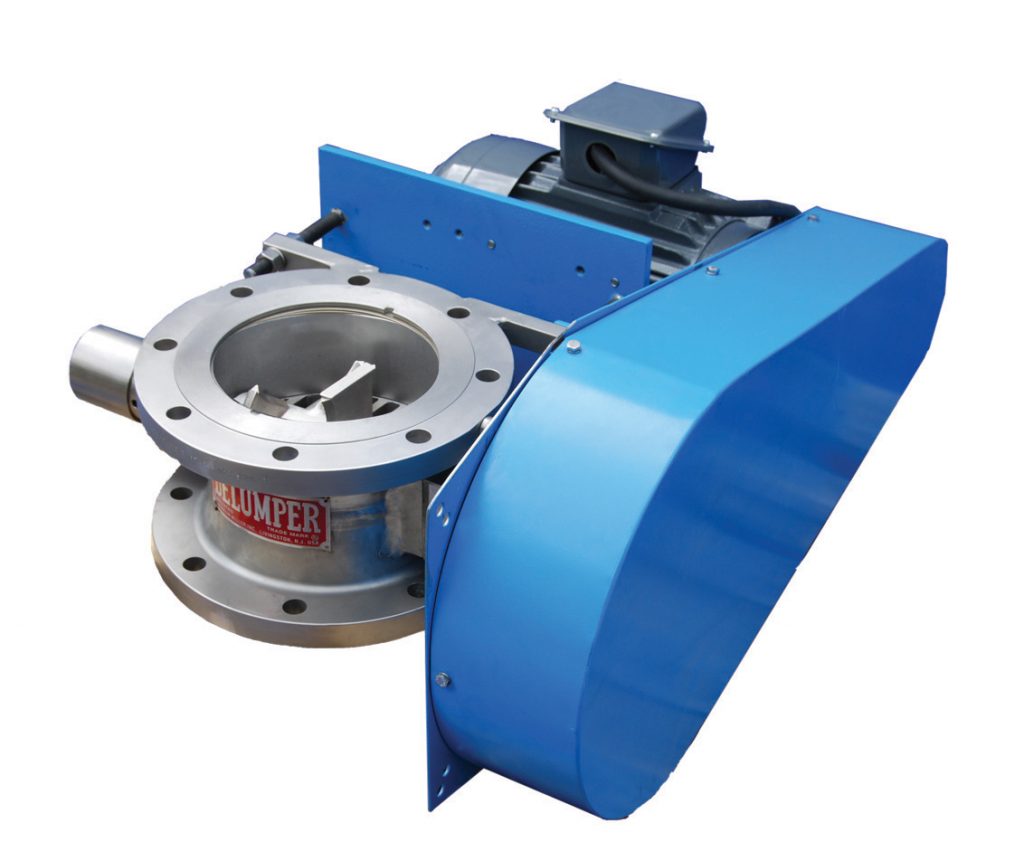

DELUMPER® lump breakers and crushers break solids, lumps and agglomerates down to desired size with a once-through, non-churning, crushing action that produces minimal fines. They can reduce plant downtime, increase processing speed and improve product consistency. These units are precision manufactured and aligned for smooth operation with low vibration or noise. These units are designed for inline pressure-rated service and gravity applications as part of a system or stand-alone.

These processors can eliminate blockages, bridging, jamming and plugging. Bagged powders often get lumps and agglomerates when transported or stored. DELUMPER Crushers play an important role in restoring and freshening a variety of materials. These materials include waxes, resins, salt, foods, fertilizers, coal, filter cake, chemicals, urea, ammonium nitrate, sugar, salts, chocolate,colors, plastics, pharmaceuticals, soda ash, limestone, coal, fly ash, potash,phosphates, agglomerated powders, filter cake, and more without over grind.

Our equipment enhances the operation of mixing, drying and conveying equipment. DELUMPER crushers and lump breakers reduce solids, lumps and agglomerates down to desired size with a once-through, non-churning, crushing action that produces minimal fines. They can reduce plant downtime, increase processing speed and improve product consistency.

Sewage and Wastewater Grinders

Franklin Miller’s broad range of grinders and comminutors are designed for both reliability and ease of maintenance. Backed by 100 years of service and technology, these units deliver superior performance, durability and exclusive features.

Franklin Miller grinders reduce a wide variety of materials including sanitary wipes,rags, wood, paper, sludge and more. These units are proven to reduce pump clogging, protect process and dewatering equipment, reduce solids and keep wastewater systems running smoothly. Applications include: wastewater headworks, sludge, recirculation, septage receiving, protecting of dewatering equipment such as belt filter presses and centrifuges, as well as a variety of industrial applications including fish processing, bio-solids, oil transfer and more.

Industrial Shredders

TASKMASTER® industrial shredders are used for a broad range of applications. They are known worldwide for their efficiency, durability and reliable performance. TASKMASTER Shredders aid in the safe disposal of sensitive, substandard or hazardous materials. They can reduce bulk waste solids, liquid and solid waste as well as sludge and biosolids.

TASKMASTER industrial shredders deliver remarkable shredding capabilities. These units can reduces a wide variety of bulk solids up to 80%. Applications include food waste, pallets, steel drums, bulk waste, packaging, plastic, wood and paper,electronic components and more.

TASKMASTER shredders generally employs no sizing screen so the output particle is determined by the cutter shape. Taskmaster cutters are precision manufactured to exacting standards to provide optimal shredding and long life. Each Taskmaster is heavily constructed for low deflection or vibration and quiet operation.

TASKMASTER industrial shredders employ two parallel counter rotating stacks of cutters that intermesh at low speed under extremely high torque. As the cam shaped cutters intermesh at close clearance, they cut, shear, tear, slice, and rip apart a variety of materials into smaller pieces typically in a strip or chip-like output shape. The geometry of this dual-shaft cutter also provides excellent feeding characteristics for a variety of solids.

For more information, contact us at our Manchester office: +44 (0) 161 302 7055

Or in the USA: USA 001-973-535-9200